LB-100

Labo

| Availability: | |

|---|---|

Introduction:

*Patent equipment, high speed.

*Feed roll paper,

*Auto creasing(guide line),

*Auto emboss (logo and shape on lid top, also make cross cut),

*Auto punching(cut roll paper to lid disc),

*Lid made by one paper disc, save cost.

*PLC control + servo motor feed paper

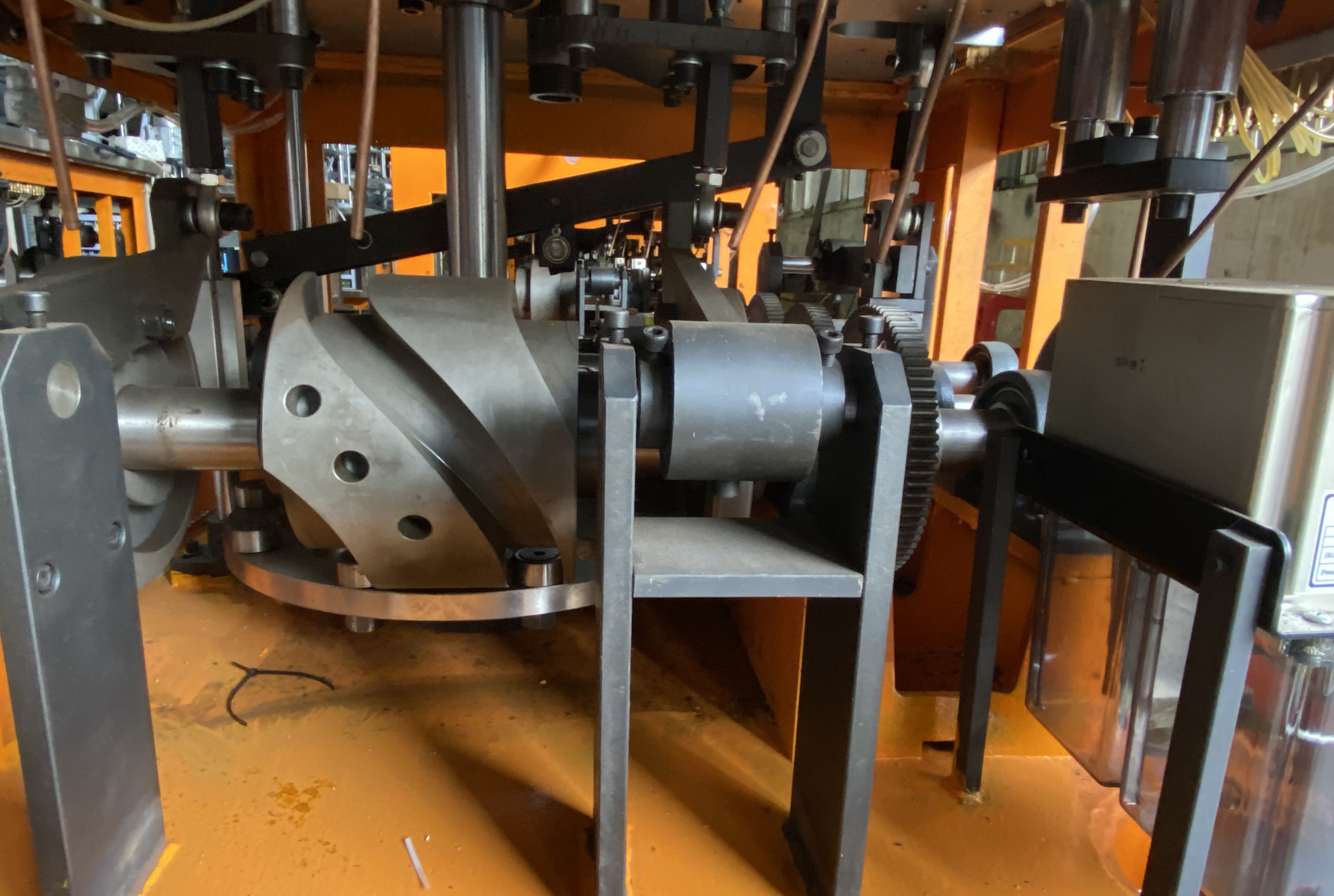

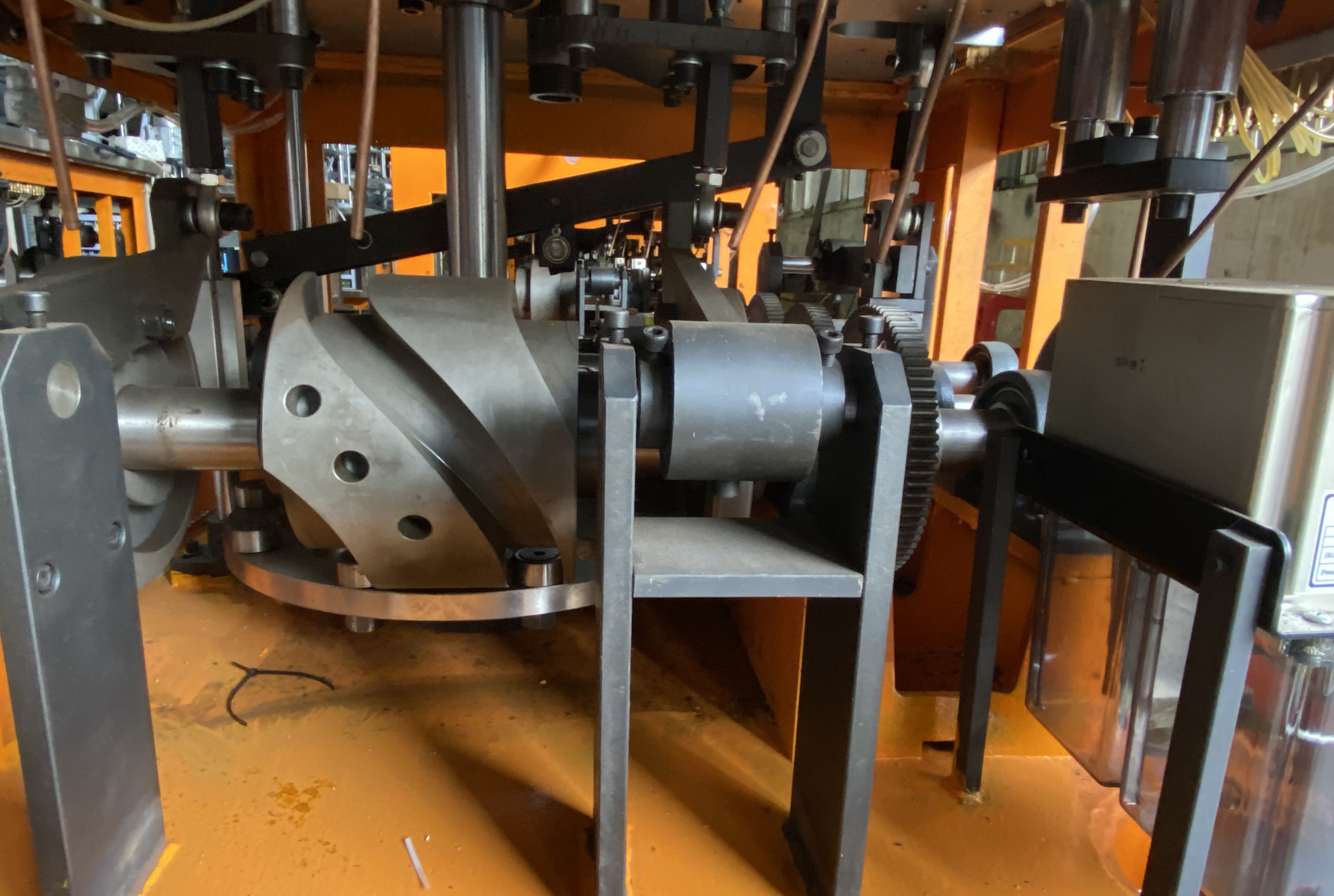

*Open cam + shaft + cam + gear control movement, stable and reliable.

Machine Detailed Pic:

Roll Feeding

Lid Forming Part

Strong Mechanical Part

Collection Part

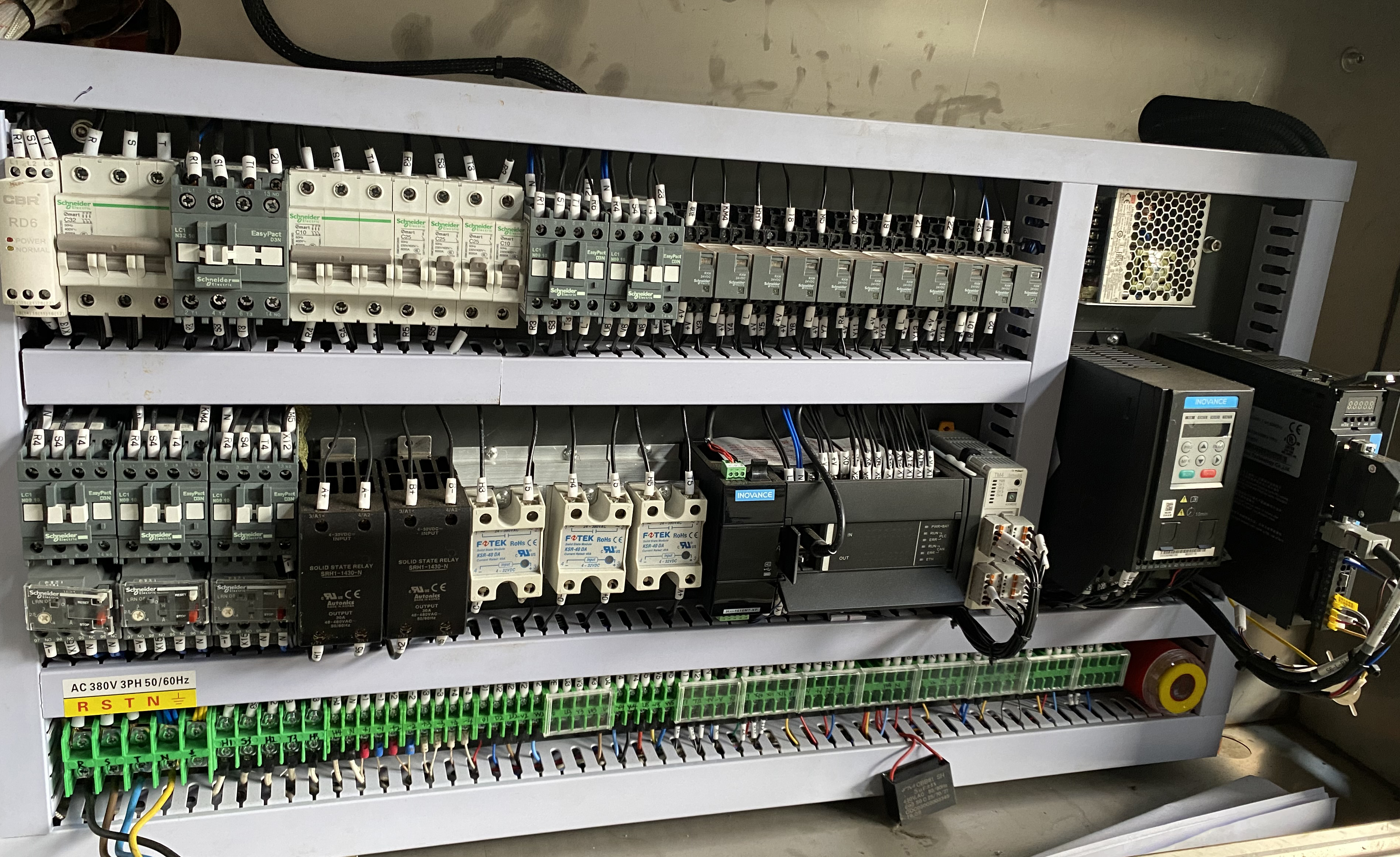

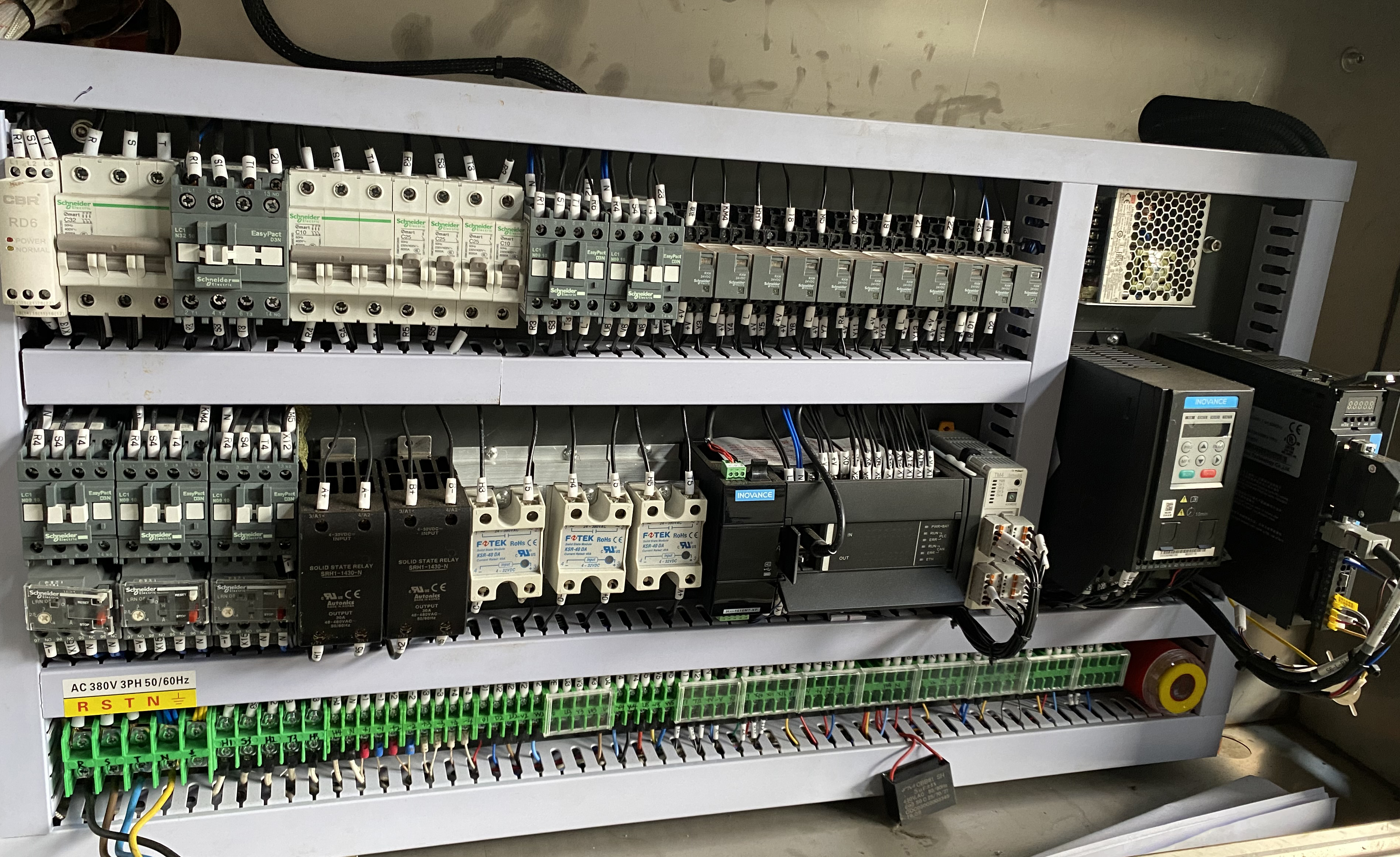

Electric Part

Machine pic for reference

Introduction:

*Patent equipment, high speed.

*Feed roll paper,

*Auto creasing(guide line),

*Auto emboss (logo and shape on lid top, also make cross cut),

*Auto punching(cut roll paper to lid disc),

*Lid made by one paper disc, save cost.

*PLC control + servo motor feed paper

*Open cam + shaft + cam + gear control movement, stable and reliable.

Machine Detailed Pic:

Roll Feeding

Lid Forming Part

Strong Mechanical Part

Collection Part

Electric Part

Machine pic for reference

Introducing our state-of-the-art Paper Cup Lid Making Forming Machine, designed to revolutionize your lid production process. With a professional tone of voice, we proudly present a product description that highlights the exceptional features of our machine.

Equipped with advanced technology, our Paper Cup Lid Making Forming Machine offers an automated solution for all your lid manufacturing needs. The automatic roll paper feed ensures a seamless and efficient operation, saving you valuable time and effort.

This machine boasts a range of impressive features, including creasing, embossing, crosscutting, and punching capabilities. With these functionalities, you can effortlessly create lids of various sizes and styles, catering to the diverse requirements of your customers.

The auto feed disc to mold mechanism further enhances the efficiency of the process, ensuring a smooth transition from one stage to another. Additionally, the heating, folding, knurling, and discharge functions are seamlessly integrated into the machine, providing a hassle-free lid production experience.

To streamline the collection process, our Paper Cup Lid Making Forming Machine comes with a convenient convey and counter system. This feature enables easy retrieval and accurate counting of the produced lids, allowing you to maintain an organized workflow and meet your production targets efficiently.

With our machine, you can be confident in the quality and consistency of your lid production. The professional tone of voice reflects our commitment to delivering a reliable and high-performing product that meets the standards of your industry.

Invest in our Paper Cup Lid Making Forming Machine and experience the advantages of automation, efficiency, and precision in your lid manufacturing process. Stay ahead of the competition and elevate your business to new heights with our cutting-edge solution.

Introducing our state-of-the-art Paper Cup Lid Making Forming Machine, designed to revolutionize your lid production process. With a professional tone of voice, we proudly present a product description that highlights the exceptional features of our machine.

Equipped with advanced technology, our Paper Cup Lid Making Forming Machine offers an automated solution for all your lid manufacturing needs. The automatic roll paper feed ensures a seamless and efficient operation, saving you valuable time and effort.

This machine boasts a range of impressive features, including creasing, embossing, crosscutting, and punching capabilities. With these functionalities, you can effortlessly create lids of various sizes and styles, catering to the diverse requirements of your customers.

The auto feed disc to mold mechanism further enhances the efficiency of the process, ensuring a smooth transition from one stage to another. Additionally, the heating, folding, knurling, and discharge functions are seamlessly integrated into the machine, providing a hassle-free lid production experience.

To streamline the collection process, our Paper Cup Lid Making Forming Machine comes with a convenient convey and counter system. This feature enables easy retrieval and accurate counting of the produced lids, allowing you to maintain an organized workflow and meet your production targets efficiently.

With our machine, you can be confident in the quality and consistency of your lid production. The professional tone of voice reflects our commitment to delivering a reliable and high-performing product that meets the standards of your industry.

Invest in our Paper Cup Lid Making Forming Machine and experience the advantages of automation, efficiency, and precision in your lid manufacturing process. Stay ahead of the competition and elevate your business to new heights with our cutting-edge solution.

Suitable Paper | One & Two side PE coated paper, glossy coated paper. |

Forming Size | Height (8-15)mm, Diameter (60-100)mm |

Paper Weight | 250~350 gsm |

Lid Height | 8~15 mm |

Speed | 70~100 pcs/minute |

Power Source | AC380V 3-phase, 50Hz |

Total power | 10KW |

Weight | 2500KGS |

Overall dimensions | 2600*1500*1800mm |

Air requirement | Consumption 0.02cubic meter/minute, Pressure:0.3MPa |

Suitable Paper | One & Two side PE coated paper, glossy coated paper. |

Forming Size | Height (8-15)mm, Diameter (60-100)mm |

Paper Weight | 250~350 gsm |

Lid Height | 8~15 mm |

Speed | 70~100 pcs/minute |

Power Source | AC380V 3-phase, 50Hz |

Total power | 10KW |

Weight | 2500KGS |

Overall dimensions | 2600*1500*1800mm |

Air requirement | Consumption 0.02cubic meter/minute, Pressure:0.3MPa |

Main Motor | Suzhou |

Low-appliance Voltage | France Schneider |

Servo Motor | Shenzhen Inovance |

PLC Controller | Shenzhen Inovance |

Inverter | Shenzhen Inovance |

Touch Screen | Shenzhen Inovance |

Pneumatic Element | Airtac |

Bearing | IKO |

Main Motor | Suzhou |

Low-appliance Voltage | France Schneider |

Servo Motor | Shenzhen Inovance |

PLC Controller | Shenzhen Inovance |

Inverter | Shenzhen Inovance |

Touch Screen | Shenzhen Inovance |

Pneumatic Element | Airtac |

Bearing | IKO |

LB 600Y-GP Hydraulic Multifunction Paper Plate Machine adopts straight-line forming, which is paper feeding, forming and collecting in one straight line. stable forming, high efficiency and labor saving.

Our machine has function of automatically complete the full process of die cutting, creasing, embssoing and stack collection. It is an ideal cutting machine

The automatic carton thermoforming machine is a fully automatic paper forming machine with the advantages of high speed and convenient operation. This model uses a self-contained hot air generator for single PE coated paper.

Our LB 1600 Automatic Double Line Paper Box Machine with firm structure,high quality,low noise and high efficiency.1600 Automatic Double Line Paper Box Machine has the full servo control. Besides, it is very fast and suit for paper box of large quantity. It adopts photoelectric system controls. In case of an error in the paper box, the gluing tray will automatically rise, and it will return to normal after one cycle.

LB-1200 Automatic Paper Box Machine is an ideal equipment for the production of carton boxes, such as hamburgers, french fries boxes, fried chicken boxes, children's lunch boxes, take-out boxes, triangular pizza boxes, etc. The structure is sturdy, good quality, low noise, and high efficiency. It has a paper feeding unit, an adjustment unit, a water unit, a forming unit, a finished product collection unit and a counting unit.