| Availability: | |

|---|---|

Machine Details

LB-400Y is an oblique double-stations paper plate machine with a stable speed of 25-35 pcs/min on one side. The speed depends on the size of the plate, the depth, the quality of the paper and the debugging level of the engineer etc. Because of its structure, this machine usually does not have a conveyor belt, but it can be customized according to customer requirements. It is an equipment suitable for making normal paper plates, paper bowls and deep trays. The machine is easy to operate and maintain, and has a high cost performance.

Plate Made from Machine for Your Reference

Machine Picture:

Two stations working separately

Plate Loader and Forming Part

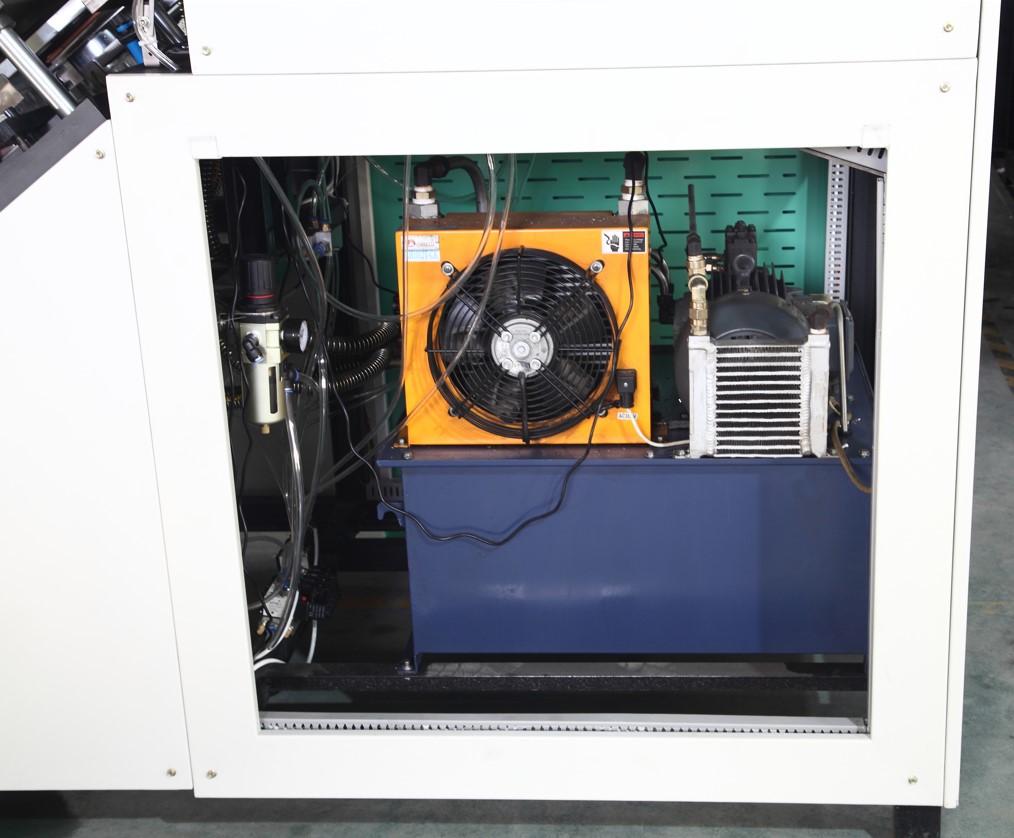

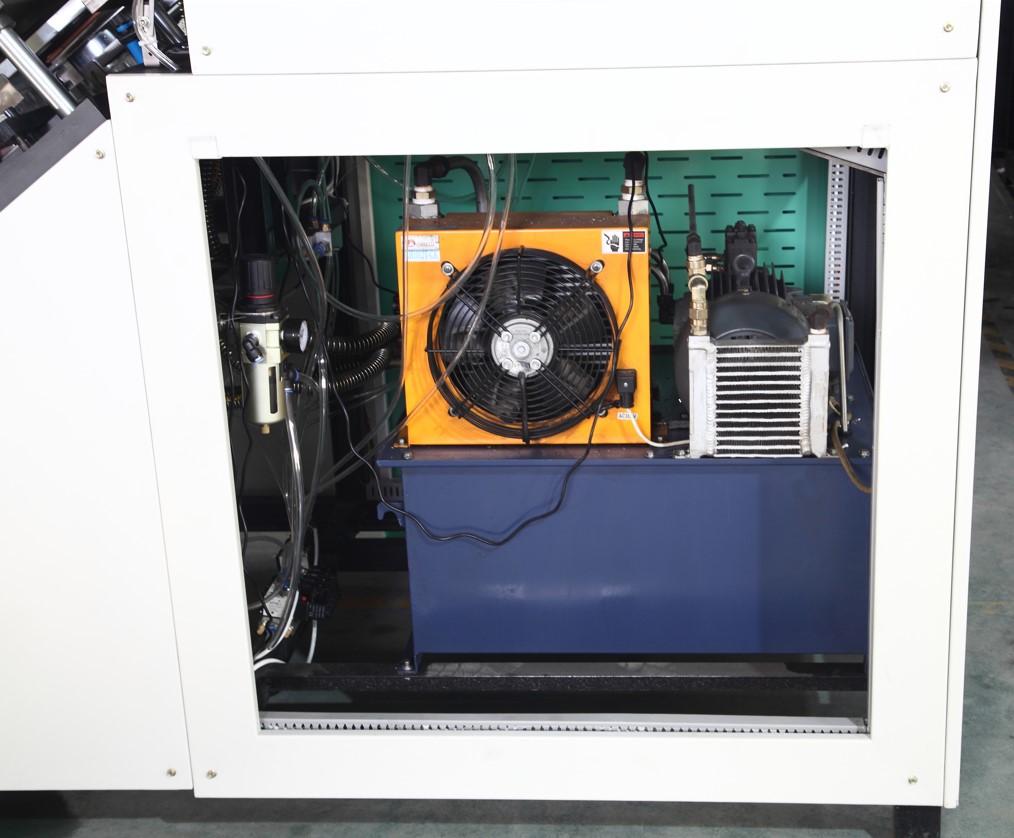

Hydraulic System

Machine pic

Machine Details

LB-400Y is an oblique double-stations paper plate machine with a stable speed of 25-35 pcs/min on one side. The speed depends on the size of the plate, the depth, the quality of the paper and the debugging level of the engineer etc. Because of its structure, this machine usually does not have a conveyor belt, but it can be customized according to customer requirements. It is an equipment suitable for making normal paper plates, paper bowls and deep trays. The machine is easy to operate and maintain, and has a high cost performance.

Plate Made from Machine for Your Reference

Machine Picture:

Two stations working separately

Plate Loader and Forming Part

Hydraulic System

Machine pic

Model | LB 400Y |

Paper Plate Size | 4-11inches |

Paper Bowl Size | depth≤55mm;diameter≤280mm(raw material size unfold) |

Capacity | 50-75Pcs/min |

Power Requirements | 380V 50HZ |

Total Power | 5KW |

Weight | 800Kg |

Specifications | 1800×1200×1700mm |

Raw Material | 160-1000g/m2(original paper, white paperboard, white cardboard, aluminum foil paper or others) |

Air Source | Working pressure0.5Mpa Working air volume 0.5m3/min |

Parameters of Cylinder | MPT-63-150-3T Oil cylinder stroke: 150mm |

Model | LB 400Y |

Paper Plate Size | 4-11inches |

Paper Bowl Size | depth≤55mm;diameter≤280mm(raw material size unfold) |

Capacity | 50-75Pcs/min |

Power Requirements | 380V 50HZ |

Total Power | 5KW |

Weight | 800Kg |

Specifications | 1800×1200×1700mm |

Raw Material | 160-1000g/m2(original paper, white paperboard, white cardboard, aluminum foil paper or others) |

Air Source | Working pressure0.5Mpa Working air volume 0.5m3/min |

Parameters of Cylinder | MPT-63-150-3T Oil cylinder stroke: 150mm |

No. | PARTS NAME | ORIGIN |

1 | Hydraulic Motor | Zhejiang Zhonglong |

2 | Temperature Controller | Shanghai Qide |

3 | PLC | Taida |

4 | Stainless Steel Heating Pipe | Jiangsu Rong Dali |

5 | Oil Pump | Taiwan |

6 | Counter Switch | Yueqing Tiangao |

7 | Normally Open Photoelectric | Shanghai Qide |

8 | Solenoid Valve | Taiwan Airtac |

9 | Bearing | Harbin |

10 | Temperature Sensor | Shanghai Xingyu |

11 | Normally Closed Photoelectric | Shanghai Qide |

12 | AC Contactor | Yueqing Tiangao |

No. | PARTS NAME | ORIGIN |

1 | Hydraulic Motor | Zhejiang Zhonglong |

2 | Temperature Controller | Shanghai Qide |

3 | PLC | Taida |

4 | Stainless Steel Heating Pipe | Jiangsu Rong Dali |

5 | Oil Pump | Taiwan |

6 | Counter Switch | Yueqing Tiangao |

7 | Normally Open Photoelectric | Shanghai Qide |

8 | Solenoid Valve | Taiwan Airtac |

9 | Bearing | Harbin |

10 | Temperature Sensor | Shanghai Xingyu |

11 | Normally Closed Photoelectric | Shanghai Qide |

12 | AC Contactor | Yueqing Tiangao |

LB 600Y-GP Hydraulic Multifunction Paper Plate Machine adopts straight-line forming, which is paper feeding, forming and collecting in one straight line. stable forming, high efficiency and labor saving.

Our machine has function of automatically complete the full process of die cutting, creasing, embssoing and stack collection. It is an ideal cutting machine

The automatic carton thermoforming machine is a fully automatic paper forming machine with the advantages of high speed and convenient operation. This model uses a self-contained hot air generator for single PE coated paper.

Our LB 1600 Automatic Double Line Paper Box Machine with firm structure,high quality,low noise and high efficiency.1600 Automatic Double Line Paper Box Machine has the full servo control. Besides, it is very fast and suit for paper box of large quantity. It adopts photoelectric system controls. In case of an error in the paper box, the gluing tray will automatically rise, and it will return to normal after one cycle.

LB-1200 Automatic Paper Box Machine is an ideal equipment for the production of carton boxes, such as hamburgers, french fries boxes, fried chicken boxes, children's lunch boxes, take-out boxes, triangular pizza boxes, etc. The structure is sturdy, good quality, low noise, and high efficiency. It has a paper feeding unit, an adjustment unit, a water unit, a forming unit, a finished product collection unit and a counting unit.