| Availability: | |

|---|---|

Introduction:

l Suitable paper: One & Two side PE coated paper, glossy coated paper.

Automatic roll paper feed, creasing (make the forming guide line), emboss (can make emboss, logo), cross cut (make hole for straw), punching (punch the roll paper to lid open disc), auto feed disc to mold, heating, folding, knurling, and discharge, With convey and counter for collection.

Machine Detailed Pic:

Roll Feeding

Lid Forming Part

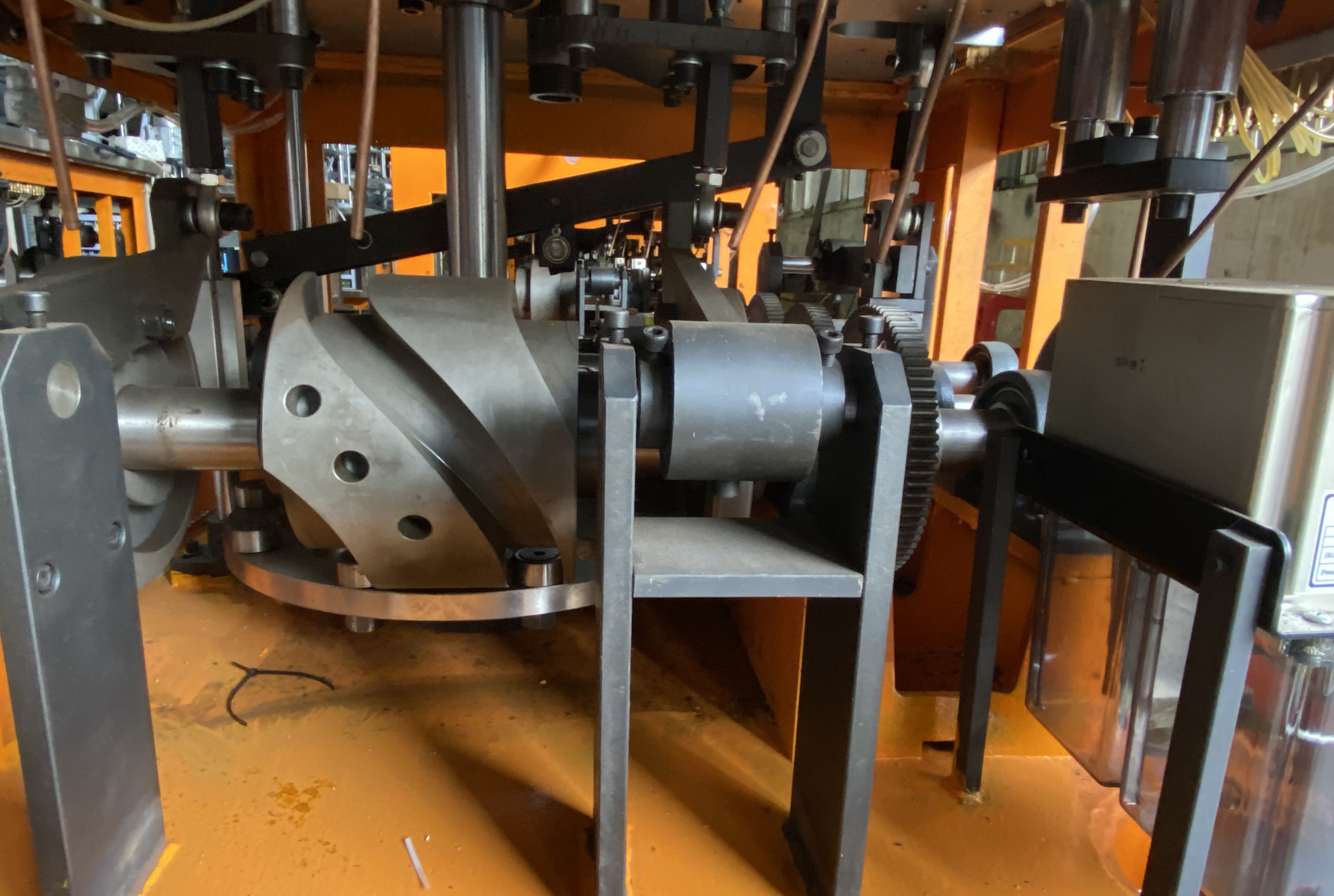

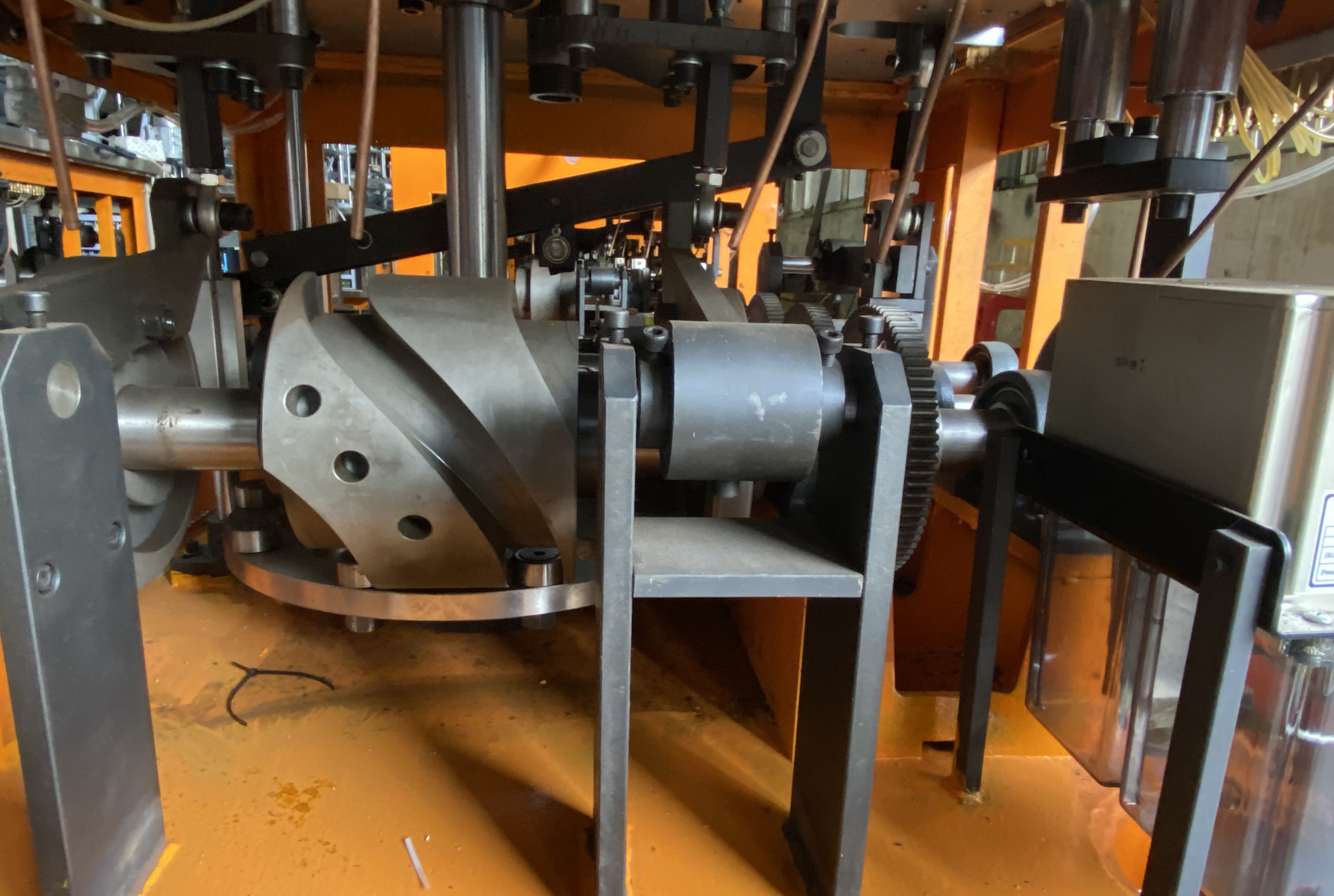

Strong Mechanical Part

Collection Part

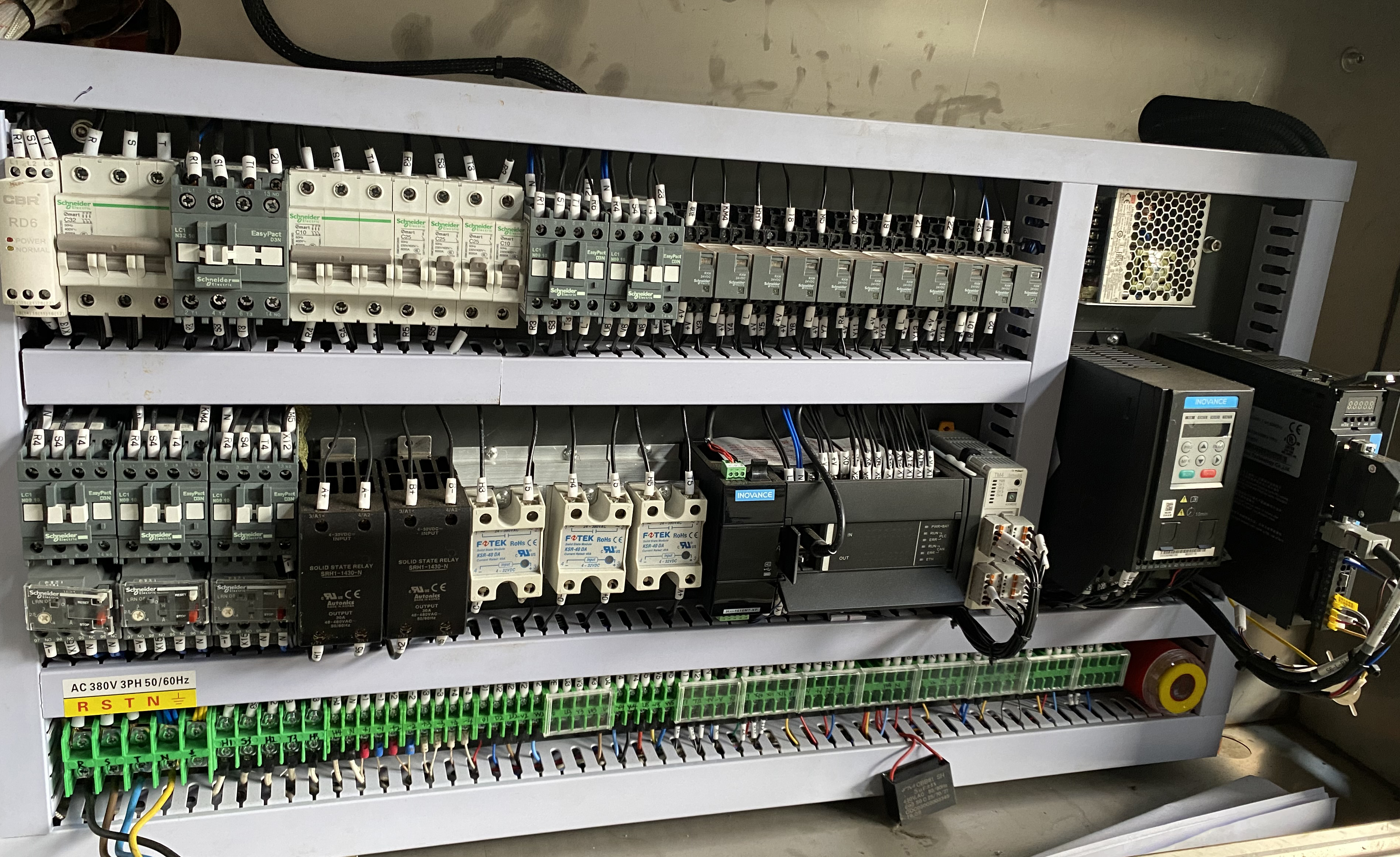

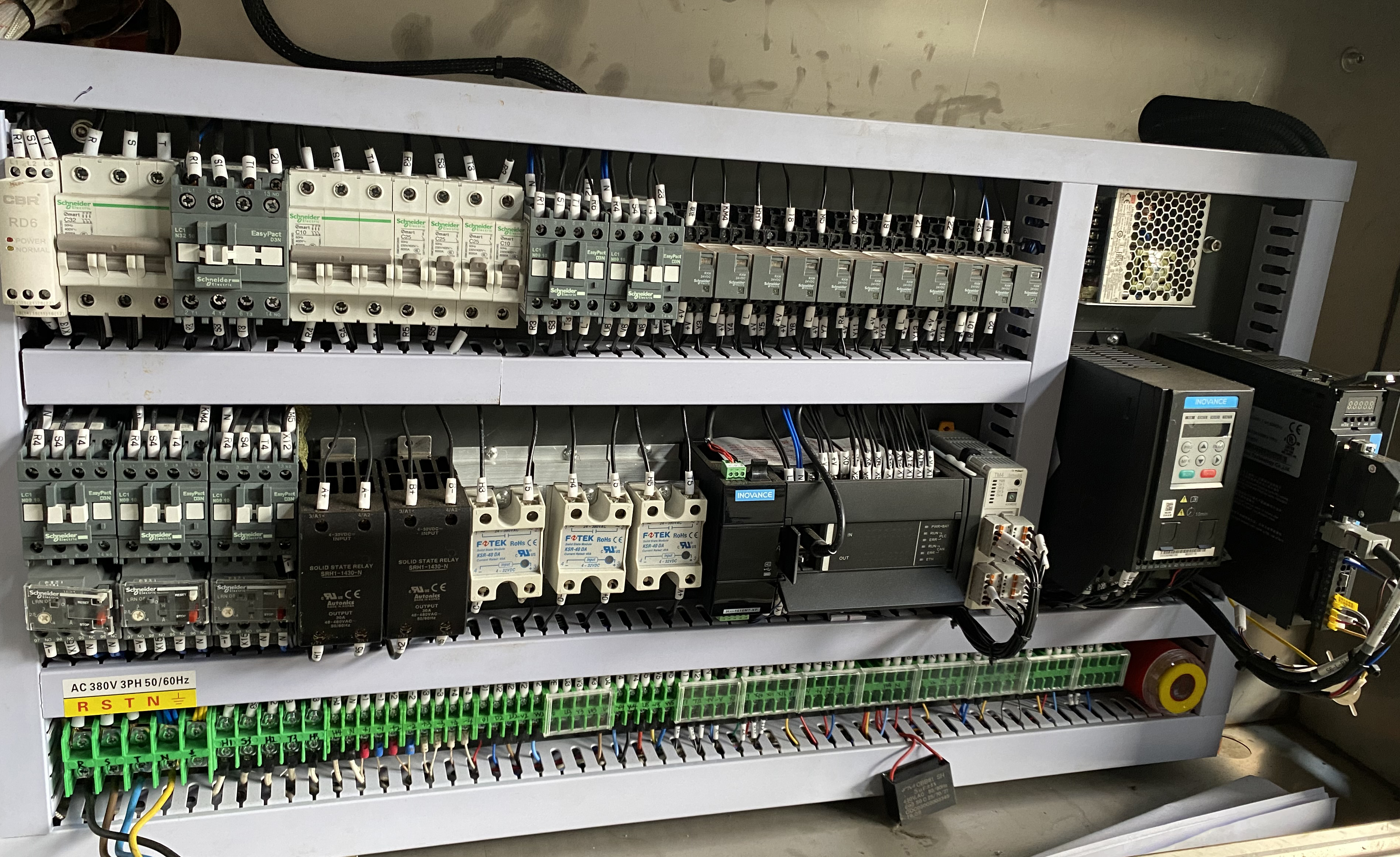

Electric Part

Machine pic for reference

Introduction:

l Suitable paper: One & Two side PE coated paper, glossy coated paper.

Automatic roll paper feed, creasing (make the forming guide line), emboss (can make emboss, logo), cross cut (make hole for straw), punching (punch the roll paper to lid open disc), auto feed disc to mold, heating, folding, knurling, and discharge, With convey and counter for collection.

Machine Detailed Pic:

Roll Feeding

Lid Forming Part

Strong Mechanical Part

Collection Part

Electric Part

Machine pic for reference

Suitable Paper | One & Two side PE coated paper, glossy coated paper. |

Forming Size | Height (8-15)mm, Diameter (100-140)mm |

Paper Weight | 250~350 gsm |

Lid Height | 8~15 mm |

Speed | 60-75 pcs/minute |

Power Source | AC380V 3-phase, 50Hz |

Total power | 10KW |

Weight | 2500KGS |

Overall dimensions | 2600*1500*1800mm |

Air requirement | Consumption 0.02cubic meter/minute, Pressure:0.3MPa |

Suitable Paper | One & Two side PE coated paper, glossy coated paper. |

Forming Size | Height (8-15)mm, Diameter (100-140)mm |

Paper Weight | 250~350 gsm |

Lid Height | 8~15 mm |

Speed | 60-75 pcs/minute |

Power Source | AC380V 3-phase, 50Hz |

Total power | 10KW |

Weight | 2500KGS |

Overall dimensions | 2600*1500*1800mm |

Air requirement | Consumption 0.02cubic meter/minute, Pressure:0.3MPa |

Main Motor | Suzhou |

Low-appliance Voltage | France Schneider |

Servo Motor | Shenzhen Inovance |

PLC Controller | Shenzhen Inovance |

Inverter | Shenzhen Inovance |

Touch Screen | Shenzhen Inovance |

Pneumatic Element | Airtac |

Bearing | IKO |

Main Motor | Suzhou |

Low-appliance Voltage | France Schneider |

Servo Motor | Shenzhen Inovance |

PLC Controller | Shenzhen Inovance |

Inverter | Shenzhen Inovance |

Touch Screen | Shenzhen Inovance |

Pneumatic Element | Airtac |

Bearing | IKO |

LB 600Y-GP Hydraulic Multifunction Paper Plate Machine adopts straight-line forming, which is paper feeding, forming and collecting in one straight line. stable forming, high efficiency and labor saving.

Our machine has function of automatically complete the full process of die cutting, creasing, embssoing and stack collection. It is an ideal cutting machine

The automatic carton thermoforming machine is a fully automatic paper forming machine with the advantages of high speed and convenient operation. This model uses a self-contained hot air generator for single PE coated paper.

Our LB 1600 Automatic Double Line Paper Box Machine with firm structure,high quality,low noise and high efficiency.1600 Automatic Double Line Paper Box Machine has the full servo control. Besides, it is very fast and suit for paper box of large quantity. It adopts photoelectric system controls. In case of an error in the paper box, the gluing tray will automatically rise, and it will return to normal after one cycle.

LB-1200 Automatic Paper Box Machine is an ideal equipment for the production of carton boxes, such as hamburgers, french fries boxes, fried chicken boxes, children's lunch boxes, take-out boxes, triangular pizza boxes, etc. The structure is sturdy, good quality, low noise, and high efficiency. It has a paper feeding unit, an adjustment unit, a water unit, a forming unit, a finished product collection unit and a counting unit.