FD series automatic roll punching machine based on international advanced technology, it’s widely used in printing, packaging and paper products industries. It adopts micro-computer, human-computer control interface, servo positioning, alternating current frequency converter, manual pneumatic lock plate, photoelectric correcting deviation system, centralized oil lubrication. All the key parts and controls of the machine are imported.

| Availability: | |

|---|---|

Introduction:

Roll Die Printing And Punching Machine based on international advanced technology, it’s widely used in printing, packaging and paper products industries. It adopts micro-computer, human-computer control interface, servo positioning, alternating current frequency converter, manual pneumatic lock plate, photoelectric correcting deviation system, centralized oil lubrication. All the key parts and controls of the machine are imported.

Machine Detailed Pic

Strong Structure

Lubri cation System

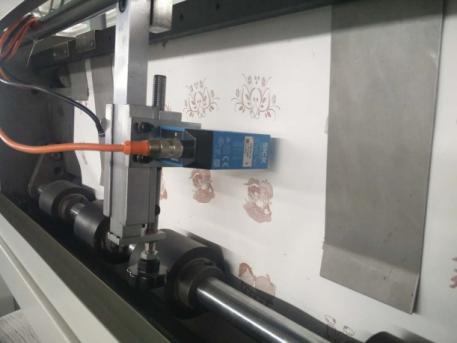

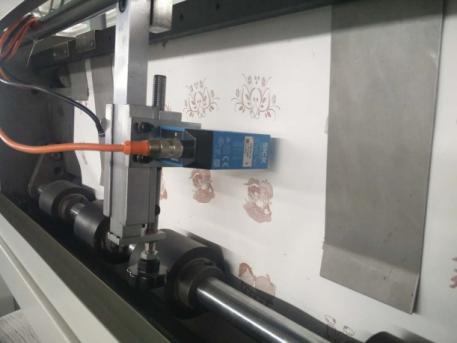

Photoelectric Sensor

Die cutting mold

Introduction:

Roll Die Printing And Punching Machine based on international advanced technology, it’s widely used in printing, packaging and paper products industries. It adopts micro-computer, human-computer control interface, servo positioning, alternating current frequency converter, manual pneumatic lock plate, photoelectric correcting deviation system, centralized oil lubrication. All the key parts and controls of the machine are imported.

Machine Detailed Pic

Strong Structure

Lubri cation System

Photoelectric Sensor

Die cutting mold

Electric Configuration:

PLC | Taiwan Delta |

Servo Motor | Taiwan Delta |

Touch screen | FLEXEM |

Frequency converter | Taiwan Delta |

Switch | Taiwan Delta |

Main motor | Taiwan |

Feeding motor | Taiwan |

Contactor | Eaton |

Relay | Weidmuller |

Button | Eaton |

Electric Configuration:

PLC | Taiwan Delta |

Servo Motor | Taiwan Delta |

Touch screen | FLEXEM |

Frequency converter | Taiwan Delta |

Switch | Taiwan Delta |

Main motor | Taiwan |

Feeding motor | Taiwan |

Contactor | Eaton |

Relay | Weidmuller |

Button | Eaton |

Characteristics:

1) Adopt the anilox roller to spread ink.

2) Unwinding tension is controlled by automatic tension controller from Japan Mitsubishi.

3) Each printing unit adopt 360°for registration.

4) Each printing unit have one IR dryer

5) The rubber roller can break away automatically while parking, and run at a low speed in order to avoid ink being dry.

6) The main motor is adopted the import stepless regulation of frequency conversion.

7) Unwinding, web guiding, printing, IR drying and punching can be finished in one process

Printing Unit Parameters:

Web width | 850mm |

Print width | 840mm |

Unwind Diameter max | 1200mm |

Press Speed max (Production speed depending on process, job etc. | 80m/min |

Gear Pitch | 1/8” (3.175mm) |

Flexo Print Units (IR dryer): | 3 |

Min.Max repeat Print Cylinder | 10” - 22.5” |

Web Guiding: number | 1 |

Overprint precision | ±0.15mm |

Machine weight | 4500kg |

Characteristics:

1) Adopt the anilox roller to spread ink.

2) Unwinding tension is controlled by automatic tension controller from Japan Mitsubishi.

3) Each printing unit adopt 360°for registration.

4) Each printing unit have one IR dryer

5) The rubber roller can break away automatically while parking, and run at a low speed in order to avoid ink being dry.

6) The main motor is adopted the import stepless regulation of frequency conversion.

7) Unwinding, web guiding, printing, IR drying and punching can be finished in one process

Printing Unit Parameters:

Web width | 850mm |

Print width | 840mm |

Unwind Diameter max | 1200mm |

Press Speed max (Production speed depending on process, job etc. | 80m/min |

Gear Pitch | 1/8” (3.175mm) |

Flexo Print Units (IR dryer): | 3 |

Min.Max repeat Print Cylinder | 10” - 22.5” |

Web Guiding: number | 1 |

Overprint precision | ±0.15mm |

Machine weight | 4500kg |

LB 600Y-GP Hydraulic Multifunction Paper Plate Machine adopts straight-line forming, which is paper feeding, forming and collecting in one straight line. stable forming, high efficiency and labor saving.

Our machine has function of automatically complete the full process of die cutting, creasing, embssoing and stack collection. It is an ideal cutting machine

The automatic carton thermoforming machine is a fully automatic paper forming machine with the advantages of high speed and convenient operation. This model uses a self-contained hot air generator for single PE coated paper.

Our LB 1600 Automatic Double Line Paper Box Machine with firm structure,high quality,low noise and high efficiency.1600 Automatic Double Line Paper Box Machine has the full servo control. Besides, it is very fast and suit for paper box of large quantity. It adopts photoelectric system controls. In case of an error in the paper box, the gluing tray will automatically rise, and it will return to normal after one cycle.

LB-1200 Automatic Paper Box Machine is an ideal equipment for the production of carton boxes, such as hamburgers, french fries boxes, fried chicken boxes, children's lunch boxes, take-out boxes, triangular pizza boxes, etc. The structure is sturdy, good quality, low noise, and high efficiency. It has a paper feeding unit, an adjustment unit, a water unit, a forming unit, a finished product collection unit and a counting unit.